Mechanical splices ULTIMODE FAST-MS1 are used for permanent connections of optical fibers without the need

of employing fusion splicers. Everything the installer has to do before

application of the splice is to remove the protective layers (jacket and

aramid fibers), strip the buffer, clean the core cladding and cleave

the fiber with the two active layers.

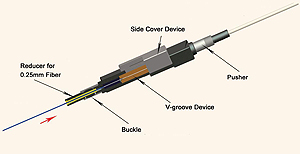

The main components of Ultimode FAST-MS1 L5550 mechanical splice

The prepared ends of the fibers to be spliced should then be inserted to the both sides of the L5550

mechanical splice. The body of the splice contains V-groove device with

holes slightly larger than the fibers. These holes are filled with

optical gel compensating for cutting imperfections and imprecise

positioning. After full insertion of the fibers, they have to be locked

with the buckles. The versatile design of the mechanical splice allows

for splicing optical fibers with buffer coating diameters of 0.25 mm

(using the included reducer) and 0.9 mm.

No comments:

Post a Comment